Image source: Canva.com

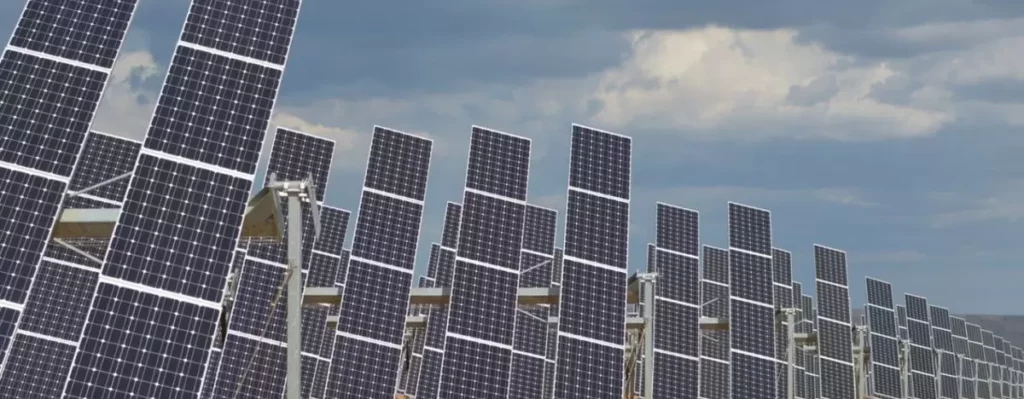

Photovoltaics (commonly known as PV) derives its name from the process of converting light (photons) into electricity (voltage), a phenomenon known as the photovoltaic effect. This effect was first harnessed in 1954 by scientists at Bell Laboratories, who developed a functional solar cell made from silicon that produced an electric current when exposed to sunlight. Initially, solar cells powered space satellites and smaller devices like calculators and watches. Today, the cost of electricity from solar cells is competitive in many areas, and large-scale photovoltaic systems are being deployed to support the electric grid.

Silicon Solar Cells

Today’s primary solar cells utilize silicon, striking a balance between cost-effectiveness and efficiency in converting sunlight into electricity. These cells are typically integrated into larger modules suitable for installation on rooftops or ground-mounted racks for utility-scale systems. Silicon stands out as the predominant semiconductor material in solar cell technology, constituting around 95% of modules sold today. It is the second most abundant material on Earth (after oxygen) and widely used in computer chips as well.

Crystalline silicon cells consist of silicon atoms arranged in a crystal lattice structure, which enhances the efficiency of converting light into electricity. These silicon-based solar cells currently offer high efficiency, affordability, and longevity. Modules are designed to maintain over 80% of their original power output after more than 25 years of operation.

Thin-Film Solar Cells

Thin-film solar cells, another widely adopted technology, utilize semiconductor materials such as cadmium telluride (CdTe) or copper indium gallium diselenide (CIGS). These cells are notable for their exceptionally thin layers, typically measuring just a few micrometers thick. Their flexibility and lightweight construction make them well-suited for portable applications like backpacks or integrated into products such as solar windows. Some types of thin-film solar cells benefit from energy-efficient manufacturing processes that facilitate scalability.

These cells are created by depositing one or more thin layers of photovoltaic material onto a supportive substrate such as glass, plastic, or metal. Currently, two main types of thin-film PV semiconductors dominate the market: cadmium telluride (CdTe) and copper indium gallium diselenide (CIGS). Both materials can be directly deposited onto either the front or back surface of the module.

CdTe is the second most common PV material after silicon, offering cost-effective manufacturing processes. However, its efficiency rates are slightly lower compared to silicon. On the other hand, CIGS cells exhibit promising properties for PV applications and demonstrate high efficiencies in laboratory settings. Yet, the challenge lies in the complexity of combining four elements, making large-scale manufacturing more intricate. Both CdTe and CIGS cells require robust protection to ensure prolonged outdoor operation, unlike silicon which is inherently more durable in various environmental conditions.

III-V Solar Cells

III-V solar cells derive their name from the elements they contain—Group III (e.g., gallium, indium) and Group V (e.g., arsenic, antimony). These cells are renowned for their exceptional conversion efficiencies despite higher production costs. They are extensively used in applications such as satellites, unmanned aerial vehicles, and other scenarios where achieving a high power-to-weight ratio is crucial.

Multijunction devices enhance efficiency by employing a high-bandgap top cell to absorb high-energy photons, while allowing lower-energy photons to pass through. Below this high-bandgap junction, a material with a slightly lower bandgap is placed to capture photons with longer wavelengths and slightly less energy. Multijunction cells typically incorporate two or more absorbing junctions, with the theoretical maximum efficiency increasing with the number of junctions.

Early research focused on multijunction devices utilized semiconductors from Group III-V elements, such as gallium indium phosphate (GaInP), gallium indium arsenide (GaInAs), and gallium arsenide (GaAs). Three-junction devices employing III-V semiconductors have achieved efficiencies exceeding 45% under concentrated sunlight. This architecture is adaptable to other solar cell technologies, with ongoing investigations exploring multijunction cells made from materials like CIGS, CdSe, silicon, organic molecules, and more.

Next-Generation Solar Cells

Next-generation solar materials offer cost-effectiveness and sustainability advantages over traditional silicon solar cells, but durability challenges persist in practical applications. A new method developed by an international team of scientists aims to streamline the development of efficient and stable perovskite solar cells. These cells derive their name from their distinctive crystalline structure, which excels at absorbing visible light.

Perovskite technology shows promise due to its ability to be manufactured at room temperature with lower energy consumption compared to conventional silicon materials.

However, a key challenge lies in the organic-inorganic metal halide materials used in these devices. These materials are vulnerable to moisture, oxygen, and heat, leading to rapid degradation in real-world conditions, the scientists cautioned.

Reliability and Grid Integration Research

Beyond efficiency and cost-effectiveness, solar cell research focuses on ensuring long-term performance and integrating photovoltaic systems into the electric grid seamlessly. Researchers at NREL address concerns related to material durability, economic viability, and grid stability, ensuring solar photovoltaics remain a dependable and sustainable energy source.

This overview highlights the diverse avenues of solar cell technology development aimed at enhancing efficiency, reducing costs, and bolstering the reliability of solar energy systems worldwide.