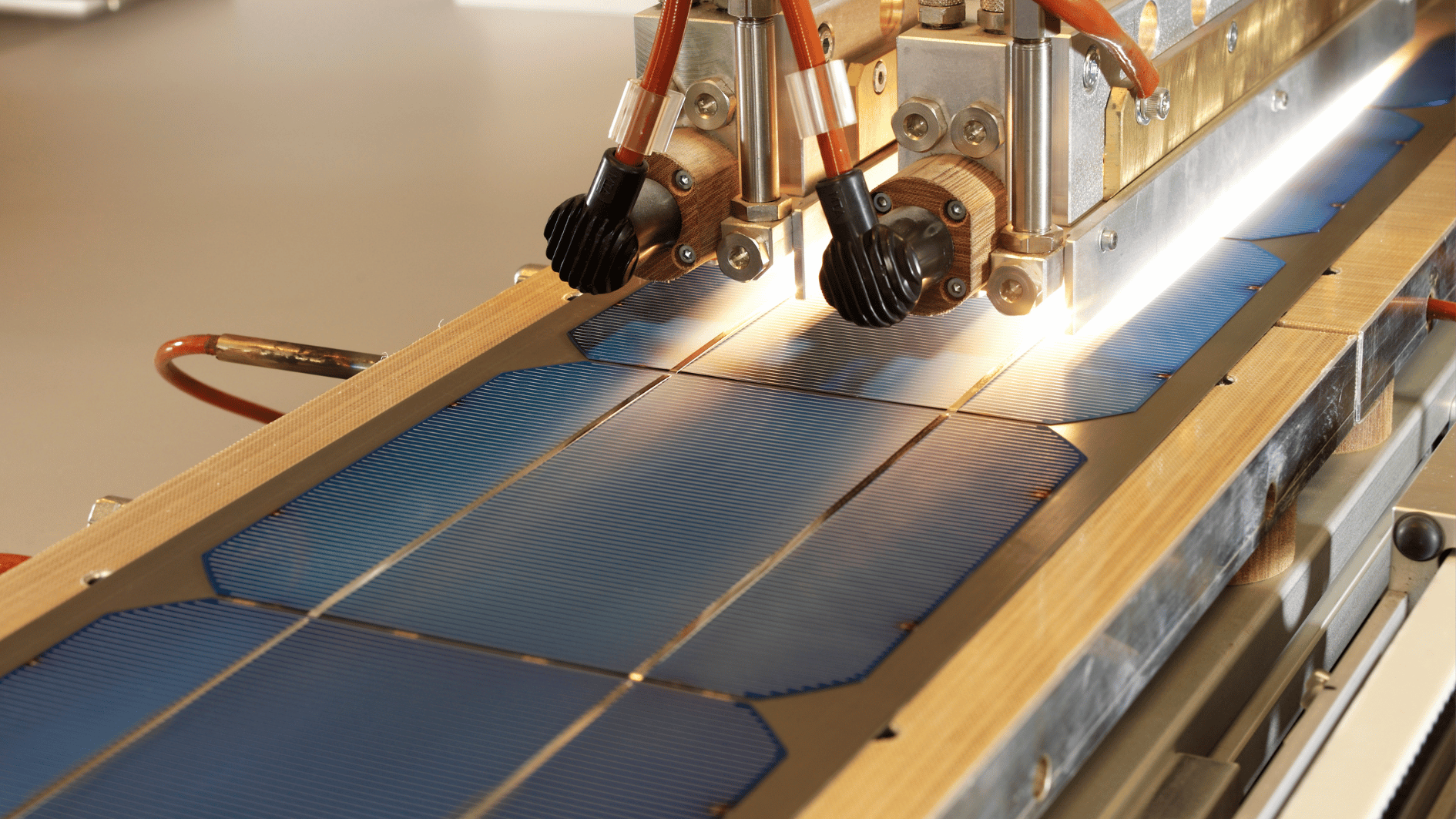

Image source: Canva.com

As the shift to renewable energy speeds up, the solar industry is working to make panel production more sustainable. While solar panels help cut carbon emissions, their manufacturing process can still impact the environment. In 2025, new efforts focus on using cleaner materials, reducing energy use, and minimizing waste. This article explores the latest advancements in eco-friendly solar panel manufacturing.

The Environmental Impact of Solar Panel Production

Raw Material Extraction and Processing

Solar panels rely on key materials such as silicon, silver, and rare metals like indium and tellurium. Mining and refining these materials involve energy-intensive processes that contribute to greenhouse gas emissions and environmental degradation.

Energy Consumption in Manufacturing

Producing photovoltaic (PV) cells requires high-temperature processing, consuming significant energy. If powered by fossil fuels, this offsets some of the climate benefits solar panels provide.

Waste Generation and Recycling Challenges

Panel production creates byproducts like silicon tetrachloride, which can be hazardous if not properly managed. Additionally, the disposal of end-of-life solar panels remains a growing challenge due to complex material separation and recycling inefficiencies.

Innovations in Sustainable Solar Manufacturing

Recycled and Low-Impact Materials

In 2025, manufacturers are increasing the use of recycled silicon and reducing reliance on rare metals, lowering environmental impact. Companies are also exploring alternatives like perovskite solar cells, which require less material and energy to produce.

Green Energy-Powered Manufacturing

Many solar panel factories are transitioning to renewable energy sources, including solar, wind, and hydroelectric power, to minimize carbon emissions during production.

Water and Chemical Usage Reduction

New manufacturing techniques, such as dry etching and closed-loop water systems, are reducing the reliance on water-intensive processes and hazardous chemicals.

Improved Recycling Programs

Advancements in solar panel recycling are enabling better material recovery, extending the life cycle of key components. Some companies are implementing take-back programs to ensure responsible disposal and reuse.

The Role of Policy and Corporate Responsibility

Government regulations and industry standards are pushing manufacturers toward sustainability. Policies promoting extended producer responsibility (EPR) require companies to manage waste and enhance recyclability. Additionally, corporate commitments to net-zero supply chains are driving investments in greener production methods.

A Greener Future for Solar Manufacturing?

While challenges remain, the solar industry is making significant strides toward sustainability. Innovations in materials, energy use, and recycling are reducing the ecological footprint of solar panel production. As technology advances and regulations tighten, 2025 marks a pivotal year in the shift toward a cleaner, more sustainable solar manufacturing process.

Key Takeaways

✅ Solar manufacturing still faces environmental challenges but is improving with eco-friendly innovations.

✅ Renewable-powered factories, material recycling, and chemical reductions are key steps forward.

✅ Policy and corporate responsibility play a crucial role in driving sustainable practices.

The journey toward truly sustainable solar energy is ongoing, but 2025 signals a strong push toward making panel production as green as the power it generates.