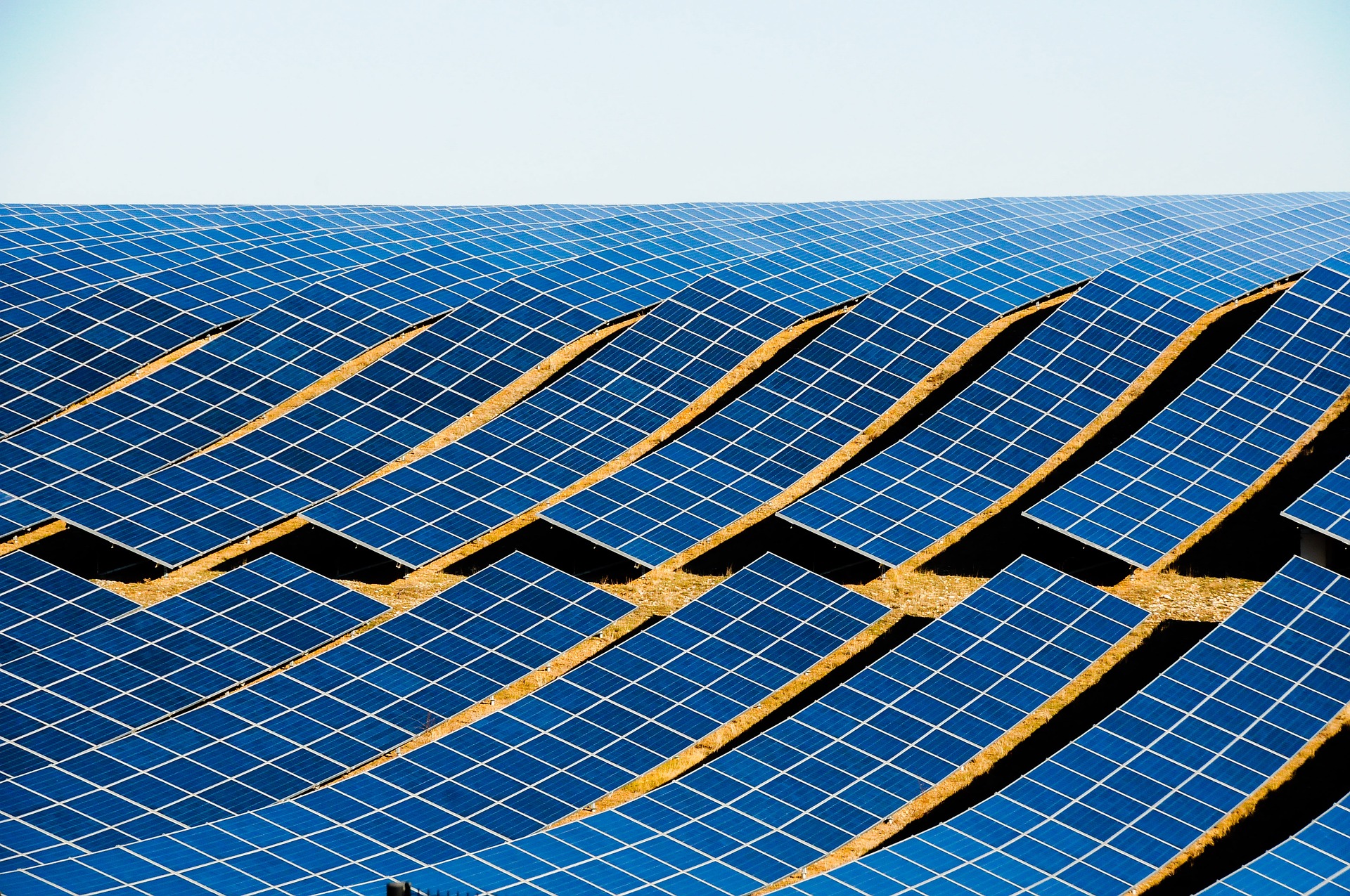

Image source: ases.org

Thin-film solar panels represent an innovative approach to harnessing solar energy, offering a flexible and lightweight alternative to traditional silicon-based photovoltaic systems. These panels, made from materials such as cadmium telluride (CdTe) or copper indium gallium selenide (CIGS), are designed to be thinner and more adaptable, making them ideal for a variety of applications where conventional panels might be impractical. As the solar industry continues to evolve, understanding the unique characteristics and considerations of thin-film technology is essential for those looking to invest in or adopt renewable energy solutions. This guide provides an overview of the key factors to consider when evaluating thin-film solar panels, including their efficiency, durability, cost-effectiveness, and suitability for different environments.

Comparison of Thin-film Solar Panels

| Panel Type | Pros | Cons |

|---|---|---|

| a-Si | Uses less material than traditional panels, including toxic materials. Highly bendable and less prone to cracks. | Much less efficient than traditional panels. |

| CdTe | Produces more energy than traditional panels. Less expensive to manufacture. | Requires cadmium, a toxic heavy metal, for production. Much less efficient than traditional silicon panels. |

| CIGS | Comparable efficiency to traditional panels. | Costly and contains toxic materials |

| OPV | Popular in building-integrated photovoltaic (BIPV) applications. Relatively affordable. | Relatively inefficient (efficiencies less than 11%) and shorter lifespans compared to other options. |

Thin-film Amorphous Silicon Solar Panels

Amorphous silicon (a-Si) solar panels differ from conventional solar panels primarily in their construction method. Instead of using solid silicon wafers (as seen in mono- or polycrystalline panels), manufacturers produce amorphous panels by depositing non-crystalline silicon (a-Si) on substrates like glass, plastic, or metal.

A single silicon layer on an amorphous solar panel can be as thin as one micrometer – thinner than a human hair! These panels rank second in popularity among thin-film options, following CdTe. Amorphous panels excel in toxicity and durability compared to counterparts but are less efficient. They are well-suited for applications requiring small loads, such as solar portable chargers and consumer electronics.

Advantages and Disadvantages of Amorphous Silicon Solar Panels

Advantages

- Minimal use of toxic materials in manufacturing.

- Require less silicon compared to conventional panels.

- Flexible and durable, less prone to cracking compared to solid silicon wafer panels.

- Ideal for small-scale applications like portable chargers and RV setups.

Disadvantages

- Lower efficiency than conventional silicon solar cells; typically around 7% conversion efficiency compared to over 20% for mono- or polycrystalline panels.

Cadmium Telluride Solar Panels

Cadmium telluride (CdTe) solar panels represent the predominant type of thin-film technology in the market. These panels consist of multiple thin layers, with a primary energy-producing layer made from cadmium telluride, surrounded by layers for electricity conduction and collection. First Solar, based in Tempe, Arizona, is a leading manufacturer of CdTe panels, capturing approximately 50% of the thin-film solar panel market.

Advantages and Disadvantages of CdTe Solar Panels

One notable advantage of CdTe panels is their high efficiency in absorbing sunlight, particularly at ideal or shorter wavelengths compared to traditional silicon cells. This enhanced absorption efficiency translates to better electricity generation potential. CdTe panels are also cost-effective to manufacture and install, making them competitive within the thin-film solar sector.

However, a significant concern with CdTe panels is their environmental impact due to cadmium, a highly toxic heavy metal. While these panels pose no direct harm during operation on rooftops and manufacturers adhere to strict safety protocols, proper disposal of old CdTe panels remains a critical issue. Additionally, CdTe panels typically exhibit lower efficiencies (around 10-11%) compared to standard silicon panels, although they surpass the efficiencies of amorphous panels.

Copper Indium Gallium Selenide (CIGS) Solar Modules

Copper indium gallium selenide (CIGS) solar modules consist of layers of copper gallium indium diselenide sandwiched between conductive layers. These thin-film materials are applied on various base layers such as glass, plastic, steel, or aluminum, creating a robust semiconductor.

Some CIGS panels feature flexible backings due to their thin layers, offering full-panel flexibility. While laboratory CIGS cells have achieved efficiency peaks of 22.4%, scaling these performance metrics remains a challenge. Initially led by Solyndra (bankrupt in 2011), today’s primary manufacturers include Solar Frontier and MiaSolé, operating in the U.S. and China.

Advantages and Disadvantages of CIGS Solar Panels

Unlike many other thin-film solar technologies, CIGS panels boast efficiencies that rival traditional silicon panels. Laboratory tests have demonstrated efficiencies exceeding 20%, positioning high-efficiency CIGS panels favorably in the global solar panel market.

Similar to CdTe panels, CIGS cells may contain the toxic chemical cadmium, albeit in lower amounts compared to other thin-film technologies. Some CIGS models substitute cadmium with zinc, enhancing their environmental friendliness.

The main drawback of CIGS panels lies in their higher production costs, which hinder their competitiveness against more economically viable silicon or CdTe panels.

Organic Photovoltaic (OPV) Cells

Organic photovoltaic (OPV) cells generate electricity using conductive organic polymers or small organic molecules. These cells employ multiple layers of thin organic vapor or solution deposited between two electrodes to facilitate electrical current.

Advantages and Disadvantages of Organic PV Cells

OPV cells are particularly popular in the expanding market of building-integrated photovoltaics (BIPV). Their versatility allows for the use of various absorbers, resulting in OPV devices available in a range of colors and even transparency. This aesthetic flexibility makes OPV a preferred choice for distinctive BIPV applications. Additionally, the abundance of materials required for organic solar cells contributes to lower manufacturing costs and market prices.

However, like other thin-film PV technologies, organic photovoltaic cells currently operate at relatively low efficiencies. Typical OPV cells achieve efficiency ratings of around 11%, and scaling up PV module production while maintaining high efficiencies remains a challenge. Much ongoing research in OPV technology focuses on enhancing efficiency. Furthermore, OPV cells generally have a shorter lifespan compared to traditional panels and other thin-film options. Addressing cell degradation, which is less prevalent in inorganic modules, continues to be a significant hurdle for organically-based photovoltaic products.

Comparing Thin-Film Solar Panels to “Traditional” Solar Panels

When evaluating thin-film panels against the more prevalent monocrystalline and polycrystalline solar panels used in residential settings, several key factors set them apart: carbon footprint, efficiency, roof space utilization, and installation costs.

Carbon Footprint

Thin-film solar panels hold a notable advantage in carbon footprint reduction compared to traditional panels. The production of thin-film panels requires less silicon, resulting in lower emissions. However, it’s important to note that some thin-film panels contain cadmium, a carcinogen, which may offset this environmental benefit. Opting for CIGS thin-film panels, which contain minimal cadmium, or selecting community solar options with CdTe technology can mitigate this concern.

Efficiency

Efficiency remains a critical consideration where traditional silicon PV panels typically achieve efficiencies between 15-22%, while thin-film panels generally range from 11-13%. This efficiency disparity affects the physical size and electricity output of your solar system.

Roof Space Utilization

Due to their lower efficiency, thin-film solar installations require more roof space to generate comparable electricity to traditional panels. Homes with ample roof area are better suited for thin-film installations, whereas standard panels can provide significant energy savings even on limited roof space.

Installation Costs

Thin-film panels offer cost savings in installation due to easier handling and reduced labor requirements. Choosing a provider with tailored mounting solutions for thin film can further enhance these savings, making thin-film installations attractive for their lower installation costs compared to traditional PV panels.

Cost Considerations and Application

Thin-film solar panels are predominantly used in commercial and utility-scale installations such as solar farms, corporate installations, and educational institutions. The economies of scale benefit thin-film technology, where larger installations offset efficiency losses with reduced installation expenses.

In residential settings, thin-film panels are viable for larger homes with adequate roof space, leveraging economies of scale and the aesthetic appeal of frameless, glass-on-glass models offered by leading manufacturers. If aesthetics are a priority and you have the space, thin-film solar can offer a cost-effective solution.

For personalized solar panel recommendations, explore SolarWiki to find the ideal match for your needs.